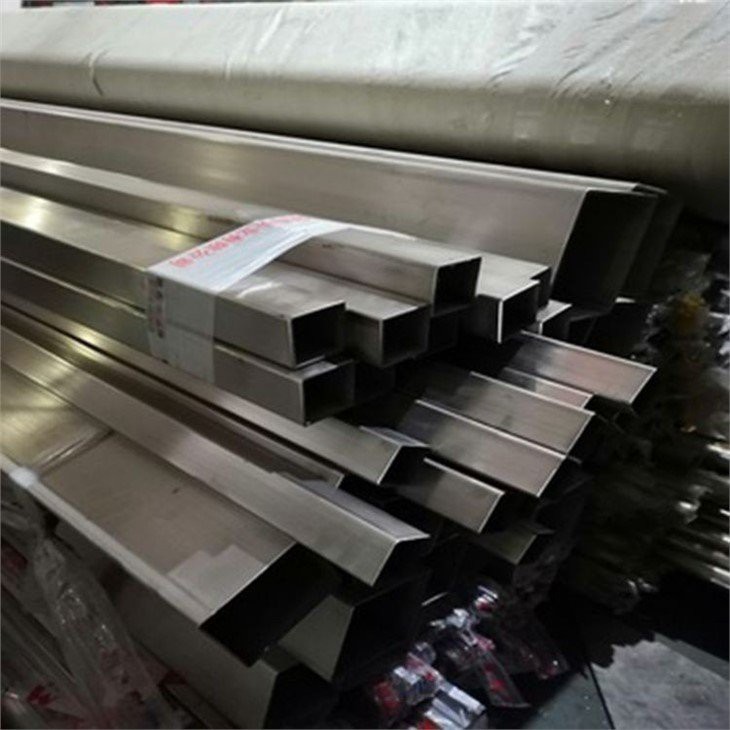

As a supplier of stainless square tubes, I often get asked about the abrasion resistance of these products. Abrasion resistance is a crucial property, especially in industries where the tubes are exposed to harsh environments, friction, or contact with abrasive materials. In this blog, I'll delve into what abrasion resistance means for stainless square tubes, the factors that affect it, and why it matters in various applications.

Understanding Abrasion Resistance

Abrasion resistance refers to a material's ability to withstand wear and tear caused by mechanical action, such as rubbing, scraping, or erosion. When it comes to stainless square tubes, a high level of abrasion resistance ensures that the tubes can maintain their structural integrity and functionality over an extended period, even under challenging conditions.

Stainless steel is known for its corrosion resistance, but its abrasion resistance is also a significant factor in its widespread use. The unique composition of stainless steel, which typically includes chromium, nickel, and other alloying elements, contributes to its ability to resist abrasion. Chromium, in particular, forms a thin, protective oxide layer on the surface of the steel, known as the passive film. This film not only protects against corrosion but also enhances the material's resistance to abrasion.

Factors Affecting Abrasion Resistance

Several factors can influence the abrasion resistance of stainless square tubes. Understanding these factors can help you choose the right type of tube for your specific application.

1. Material Composition

The composition of the stainless steel plays a vital role in determining its abrasion resistance. Different grades of stainless steel have varying amounts of alloying elements, which can affect the hardness, toughness, and overall wear resistance of the material. For example, 316 Stainless Square Tube contains molybdenum, which enhances its corrosion resistance and also improves its abrasion resistance in certain environments. On the other hand, Ss 304 Square Pipe, a popular grade of stainless steel, has good general corrosion resistance but may have slightly lower abrasion resistance compared to some other grades.

2. Surface Finish

The surface finish of the stainless square tube can also impact its abrasion resistance. A smooth surface finish reduces friction and makes it more difficult for abrasive particles to adhere to the tube, thereby improving its wear resistance. Tubes with a polished or brushed finish generally have better abrasion resistance than those with a rough or uneven surface. Additionally, surface treatments such as passivation or coating can further enhance the abrasion resistance of the tube by providing an additional layer of protection.

3. Hardness

Hardness is another important factor in abrasion resistance. Generally, harder materials are more resistant to abrasion. The hardness of stainless steel can be increased through heat treatment or by adding certain alloying elements. However, it's important to note that increasing the hardness too much can make the material more brittle, which may lead to cracking or other forms of damage under certain conditions. Therefore, a balance must be struck between hardness and toughness to ensure optimal abrasion resistance.

4. Operating Conditions

The operating conditions in which the stainless square tube is used can also have a significant impact on its abrasion resistance. Factors such as the type of abrasive material, the pressure and speed of contact, and the temperature and humidity of the environment can all affect how quickly the tube wears down. For example, tubes used in high-temperature or high-pressure applications may experience more rapid abrasion than those used in milder conditions.

Importance of Abrasion Resistance in Different Applications

Abrasion resistance is a critical property in many industries and applications where stainless square tubes are used. Here are some examples:

1. Construction

In the construction industry, stainless square tubes are commonly used for structural support, handrails, and fencing. These tubes are often exposed to harsh weather conditions, as well as contact with tools, equipment, and other materials. A high level of abrasion resistance ensures that the tubes can withstand the wear and tear associated with construction activities and maintain their appearance and functionality over time.

2. Manufacturing

In manufacturing processes, stainless square tubes are used in a variety of applications, such as conveyor systems, machinery frames, and piping. These tubes may come into contact with abrasives, such as sand, gravel, or metal particles, during the manufacturing process. Abrasion-resistant tubes can help prevent damage to the equipment and ensure smooth operation, reducing downtime and maintenance costs.

3. Food and Beverage Industry

In the food and beverage industry, stainless square tubes are used for conveying, processing, and storing food and beverage products. These tubes must be resistant to abrasion to prevent contamination of the products and to maintain the hygiene standards required by the industry. Additionally, the smooth surface finish of abrasion-resistant tubes makes them easier to clean and sanitize, further reducing the risk of bacteria growth.

4. Automotive Industry

In the automotive industry, stainless square tubes are used in exhaust systems, chassis components, and other applications. These tubes are exposed to high temperatures, vibration, and contact with road debris, which can cause abrasion and wear. Abrasion-resistant tubes can help improve the durability and performance of the automotive components, reducing the need for frequent replacements and repairs.

Choosing the Right Stainless Square Tube for Abrasion Resistance

When selecting a stainless square tube for an application that requires high abrasion resistance, it's important to consider the factors mentioned above. Here are some tips to help you make the right choice:

1. Determine the Operating Conditions

First, identify the specific operating conditions in which the tube will be used. Consider factors such as the type of abrasive material, the pressure and speed of contact, the temperature and humidity of the environment, and any other relevant factors. This will help you choose a tube with the appropriate level of abrasion resistance for your application.

2. Select the Right Grade of Stainless Steel

Based on the operating conditions, choose a grade of stainless steel that offers the best combination of abrasion resistance, corrosion resistance, and other properties. As mentioned earlier, different grades of stainless steel have varying levels of alloying elements, which can affect their abrasion resistance. Consult with a stainless steel expert or supplier to determine the most suitable grade for your needs.

3. Consider the Surface Finish

Choose a tube with a smooth surface finish to reduce friction and improve abrasion resistance. Polished or brushed finishes are often preferred, as they not only enhance the appearance of the tube but also provide better protection against abrasion. Additionally, consider surface treatments such as passivation or coating to further enhance the tube's abrasion resistance.

4. Evaluate the Hardness

While hardness is an important factor in abrasion resistance, it's important to ensure that the tube has the right balance of hardness and toughness. A tube that is too hard may be brittle and prone to cracking, while a tube that is too soft may not provide sufficient abrasion resistance. Consult with a supplier or expert to determine the appropriate hardness level for your application.

Conclusion

Abrasion resistance is a crucial property for stainless square tubes, especially in industries where the tubes are exposed to harsh environments, friction, or contact with abrasive materials. By understanding the factors that affect abrasion resistance and choosing the right type of tube for your specific application, you can ensure that the tubes can withstand the wear and tear associated with your operations and maintain their performance and functionality over time.

As a supplier of Stainless Square Pipe, I'm committed to providing high-quality products that meet the diverse needs of our customers. If you're looking for stainless square tubes with excellent abrasion resistance, please don't hesitate to contact us. We'll be happy to help you choose the right product for your application and provide you with the support and expertise you need.

References

- ASM Handbook Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys. ASM International.

- Stainless Steel: A Guide to Properties, Processing, and Applications. The Nickel Institute.

- Handbook of Stainless Steels. McGraw-Hill.