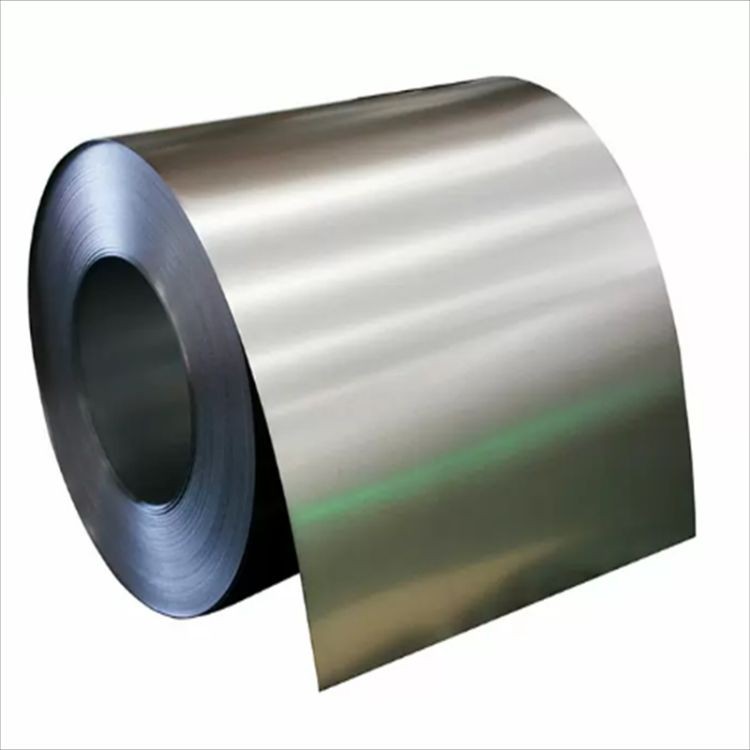

In today's world, environmental sustainability is at the forefront of many industries, and the stainless steel sector is no exception. As a stainless steel coil supplier, I've witnessed firsthand the growing interest in understanding the environmental implications of using stainless steel coil. In this blog, I'll explore the various environmental benefits of stainless steel coil and how it can contribute to a more sustainable future.

Durability and Longevity

One of the most significant environmental advantages of stainless steel coil is its exceptional durability and longevity. Stainless steel is highly resistant to corrosion, rust, and staining, even in harsh environments. This means that products made from stainless steel coil can last for decades, if not centuries, without significant degradation.

For example, in architectural applications, stainless steel coil is often used for roofing, facades, and structural components. These structures can withstand extreme weather conditions, such as heavy rain, snow, and high winds, without losing their integrity. As a result, the need for frequent replacements is minimized, reducing the demand for new materials and the associated environmental impact of manufacturing and transportation.

In industrial settings, stainless steel coil is used in a wide range of equipment, including chemical processing plants, food processing facilities, and oil and gas refineries. The corrosion resistance of stainless steel ensures that these facilities can operate safely and efficiently for extended periods, reducing the risk of leaks and spills that could harm the environment.

Recyclability

Another key environmental benefit of stainless steel coil is its high recyclability. Stainless steel is 100% recyclable, which means that it can be melted down and reused to make new products without losing its properties. In fact, stainless steel is one of the most recycled materials in the world, with a recycling rate of over 90%.

The recycling process for stainless steel is energy-efficient and produces minimal waste. When stainless steel coil reaches the end of its useful life, it can be collected and sent to a recycling facility. At the facility, the stainless steel is melted down and refined to remove impurities. The resulting molten metal can then be used to produce new stainless steel products, such as sheets, coils, and bars.

By using recycled stainless steel coil, manufacturers can reduce their energy consumption and carbon footprint. According to the International Stainless Steel Forum, recycling stainless steel saves up to 75% of the energy required to produce new stainless steel from raw materials. This not only reduces greenhouse gas emissions but also conserves natural resources.

Low Maintenance

Stainless steel coil requires minimal maintenance, which is another environmental advantage. Unlike other materials, such as wood, concrete, and painted metal, stainless steel does not require regular painting, staining, or sealing to maintain its appearance and performance. This reduces the use of chemicals and solvents, which can be harmful to the environment.

In addition, the smooth surface of stainless steel makes it easy to clean and disinfect. This is particularly important in applications where hygiene is critical, such as food processing, healthcare, and hospitality. By using stainless steel coil in these applications, businesses can reduce the use of harsh cleaning chemicals and minimize the risk of contamination.

Energy Efficiency

Stainless steel coil can also contribute to energy efficiency in various applications. In building construction, stainless steel is often used for insulation, roofing, and cladding. These materials can help to reduce heat transfer, which means that buildings require less energy for heating and cooling.

In the automotive industry, stainless steel coil is used in exhaust systems, which can improve fuel efficiency and reduce emissions. The high-temperature resistance of stainless steel allows exhaust systems to operate at higher temperatures, which improves the combustion process and reduces the amount of fuel consumed.

Reduced Waste Generation

The use of stainless steel coil can also help to reduce waste generation. As mentioned earlier, the durability and longevity of stainless steel mean that products made from it have a longer lifespan, reducing the need for frequent replacements. In addition, the recyclability of stainless steel ensures that any waste generated during the manufacturing process or at the end of a product's life can be recycled and reused.

Furthermore, stainless steel coil can be fabricated into a wide range of shapes and sizes, which means that it can be used in a variety of applications without the need for excessive cutting and waste. This reduces the amount of scrap material generated during the manufacturing process and minimizes the environmental impact of waste disposal.

Conclusion

In conclusion, there are numerous environmental benefits of using stainless steel coil. Its durability, recyclability, low maintenance, energy efficiency, and reduced waste generation make it a sustainable choice for a wide range of applications. As a stainless steel coil supplier, I'm committed to promoting the use of stainless steel as an environmentally friendly material.

If you're interested in learning more about the environmental benefits of stainless steel coil or would like to discuss your specific requirements, please feel free to [contact me for procurement and negotiation]. I'd be happy to provide you with more information and help you find the right stainless steel coil for your project.

References

- International Stainless Steel Forum. (n.d.). Stainless Steel: A Sustainable Material. Retrieved from [Website URL]

- World Steel Association. (n.d.). Steel - The Sustainable Material. Retrieved from [Website URL]

- U.S. Environmental Protection Agency. (n.d.). Recycling Basics. Retrieved from [Website URL]