Hey there! As a supplier of SS steel sheets, I've seen a lot of folks scratching their heads when it comes to choosing the right grade. It's not as straightforward as it might seem, but don't worry – I'm here to break it down for you.

First off, let's talk about what SS steel sheets are all about. Stainless steel sheets are super versatile. They're used in a ton of different industries, from construction to automotive, and even in kitchenware. The "SS" stands for stainless steel, which is basically steel with a bit of chromium added to it. This chromium forms a thin, invisible layer on the surface of the steel, protecting it from rust and corrosion.

Now, when it comes to choosing the right grade, there are a few key factors you need to consider.

1. Corrosion Resistance

One of the most important things to think about is how much corrosion resistance you need. Different grades of stainless steel have different levels of resistance to rust and corrosion. For example, if you're using the steel sheet in a marine environment, like on a boat or in a coastal building, you'll need a grade that can stand up to the salty air and water.

The 310 Stainless Steel Sheet is a great choice for high-temperature and high-corrosion environments. It has a high chromium and nickel content, which gives it excellent resistance to oxidation and scaling at elevated temperatures. So, if you're dealing with heat and corrosion at the same time, this might be the grade for you.

On the other hand, if you're using the steel sheet in a less corrosive environment, like in an indoor kitchen or a normal industrial setting, you might not need such a high level of corrosion resistance. The 420 Stainless Steel Sheet is a martensitic stainless steel that offers good corrosion resistance and high hardness. It's often used in cutlery and other applications where a sharp edge and some corrosion resistance are required.

2. Strength and Durability

Another factor to consider is the strength and durability of the steel sheet. Different grades have different mechanical properties, which means they can handle different amounts of stress and wear.

If you need a steel sheet that can withstand heavy loads or impacts, you'll want to look for a grade with high strength. Some grades are also more ductile, which means they can be bent or formed without cracking. This is important if you're planning to do any fabrication work on the steel sheet.

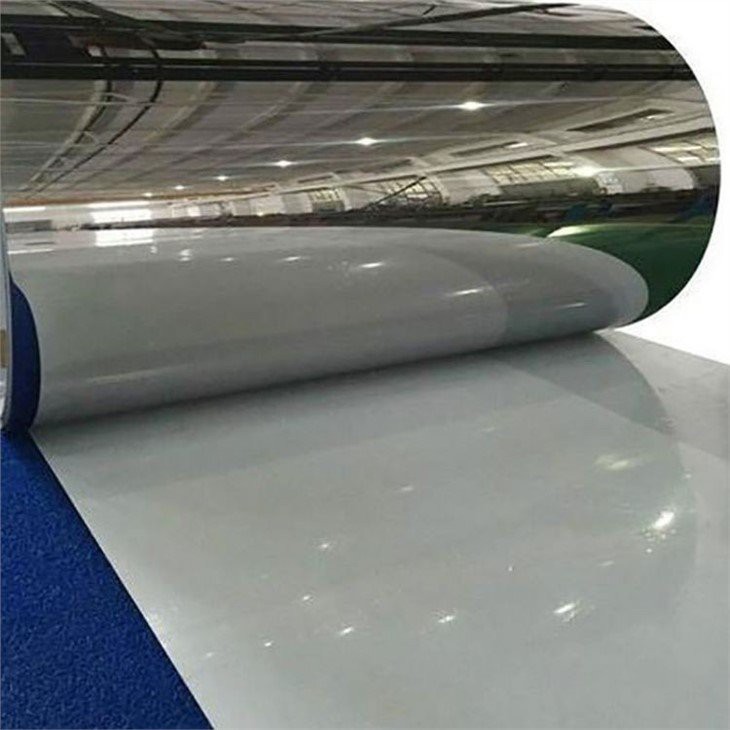

Cold-rolled steel sheets, like the Cold Rolled Stainless Steel Sheet, are often stronger and have a smoother surface finish than hot-rolled steel sheets. They're also more precise in terms of thickness and flatness, which can be important for applications where accuracy is key.

3. Cost

Let's face it, cost is always a factor. Different grades of stainless steel can vary widely in price, depending on their composition and properties. Generally, grades with higher levels of corrosion resistance and strength will be more expensive.

You need to find a balance between the performance you need and the cost you're willing to pay. Sometimes, you might be able to get away with a lower-grade steel sheet if the application doesn't require the highest level of performance. But in other cases, it might be worth investing in a more expensive grade to ensure long-term durability and reliability.

4. Aesthetic Requirements

In some applications, the appearance of the steel sheet is important. Stainless steel comes in a variety of finishes, from a smooth, mirror-like finish to a brushed or textured finish.

If you're using the steel sheet in an architectural or decorative application, you'll want to choose a finish that complements the overall design. For example, a mirror finish can give a modern and sleek look, while a brushed finish can add a more industrial or rustic touch.

5. Fabrication Requirements

Finally, you need to consider how the steel sheet will be fabricated. Different grades of stainless steel have different fabrication characteristics, such as weldability, formability, and machinability.

If you're planning to weld the steel sheet, you'll need to choose a grade that is easy to weld and doesn't require special welding techniques. Some grades are more prone to cracking or distortion during welding, so it's important to do your research and choose the right grade for the job.

Similarly, if you're going to be bending or forming the steel sheet, you'll want to choose a grade that is ductile and can be easily shaped without cracking.

So, there you have it – the key factors to consider when choosing the right grade of SS steel sheet. It's a lot to think about, but by taking the time to understand your requirements and doing your research, you can make an informed decision.

If you're still not sure which grade of SS steel sheet is right for you, don't hesitate to reach out. As a supplier, I have a lot of experience and can help you find the perfect grade for your specific application. Whether you need a small quantity for a DIY project or a large order for an industrial application, I can provide you with high-quality SS steel sheets at competitive prices.

Contact me today to start the conversation and let's find the right SS steel sheet for you!

References

- ASM Handbook, Volume 13A: Corrosion: Fundamentals, Testing, and Protection

- Stainless Steel World Magazine

- The Nickel Institute