As a seasoned supplier of stainless steel sheets, I often encounter inquiries regarding the tensile strength of these versatile materials. Tensile strength is a crucial property that determines the ability of a material to withstand pulling forces without breaking. In this blog post, I'll delve into the concept of tensile strength, explore how it applies to stainless steel sheets, and discuss the factors that influence it.

Understanding Tensile Strength

Tensile strength is defined as the maximum stress a material can withstand while being stretched or pulled before it breaks. It is typically measured in units of force per unit area, such as pounds per square inch (psi) or megapascals (MPa). To determine the tensile strength of a material, a sample is subjected to a controlled pulling force until it fractures. The maximum force applied during this process is then divided by the original cross-sectional area of the sample to calculate the tensile strength.

In the context of stainless steel sheets, tensile strength is an important consideration for a variety of applications. For example, in structural applications where the sheets are used to support heavy loads, a high tensile strength is essential to ensure the integrity and safety of the structure. Similarly, in applications where the sheets are subjected to repeated bending or stretching, such as in automotive or aerospace components, a high tensile strength helps to prevent fatigue failure.

Tensile Strength of Stainless Steel Sheets

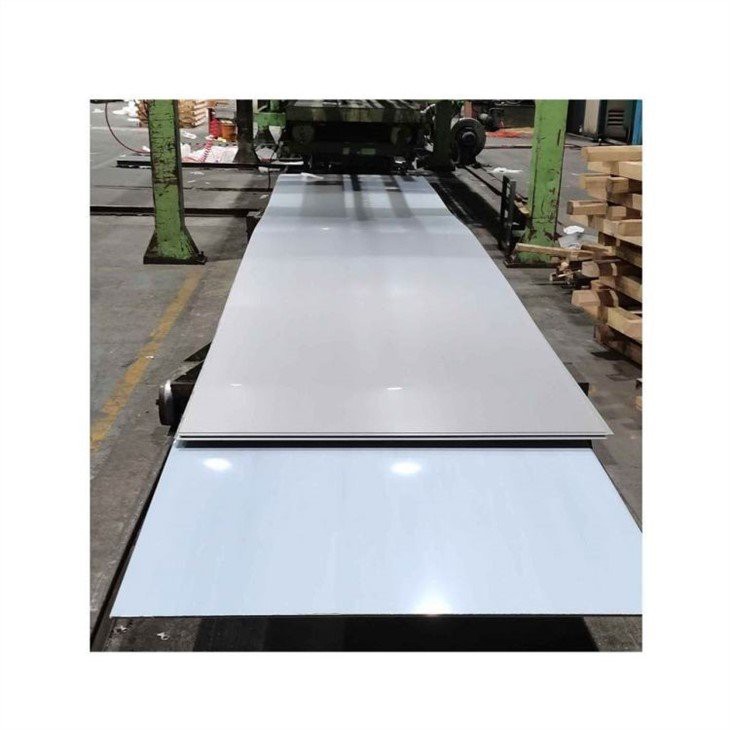

The tensile strength of stainless steel sheets can vary depending on several factors, including the grade of stainless steel, the manufacturing process, and the thickness of the sheet. Generally speaking, stainless steel sheets have a relatively high tensile strength compared to other materials, making them suitable for a wide range of applications.

One of the most common grades of stainless steel used in sheet form is 304 stainless steel. This grade has a minimum tensile strength of around 75,000 psi (517 MPa) and is known for its excellent corrosion resistance and formability. Another popular grade is 316 stainless steel, which has a slightly higher tensile strength of around 80,000 psi (552 MPa) and offers enhanced corrosion resistance in harsh environments.

In addition to these common grades, there are also specialized grades of stainless steel that offer even higher tensile strengths. For example, 310 Stainless Steel Sheet is a high-temperature grade that has a minimum tensile strength of around 85,000 psi (586 MPa) and is often used in applications where the sheets are exposed to extreme heat. Similarly, 321 Stainless Steel Sheet is a stabilized grade that has a minimum tensile strength of around 75,000 psi (517 MPa) and is commonly used in applications where the sheets are subjected to welding or high temperatures.

Factors Affecting Tensile Strength

As mentioned earlier, the tensile strength of stainless steel sheets can be influenced by several factors. One of the most significant factors is the grade of stainless steel. Different grades of stainless steel have different chemical compositions, which can affect their mechanical properties, including tensile strength. For example, grades that contain higher amounts of chromium and nickel tend to have higher tensile strengths and better corrosion resistance.

The manufacturing process also plays a role in determining the tensile strength of stainless steel sheets. Sheets that are cold rolled, for example, tend to have higher tensile strengths than those that are hot rolled. Cold rolling involves passing the sheet through a series of rollers at room temperature, which compresses the material and increases its density. This process also aligns the grain structure of the stainless steel, which can improve its strength and hardness. Cold Rolled Stainless Steel Sheet is often used in applications where a high tensile strength and a smooth surface finish are required.

The thickness of the sheet is another factor that can affect its tensile strength. Generally speaking, thicker sheets tend to have higher tensile strengths than thinner sheets. This is because thicker sheets have more material to resist the pulling forces, and the stress is distributed more evenly across the cross-sectional area of the sheet. However, it's important to note that the relationship between thickness and tensile strength is not always linear, and other factors, such as the grade of stainless steel and the manufacturing process, can also have an impact.

Importance of Tensile Strength in Applications

The tensile strength of stainless steel sheets is a critical property that can have a significant impact on the performance and durability of the final product. In structural applications, for example, a high tensile strength is essential to ensure the safety and integrity of the structure. Sheets with a low tensile strength may be more prone to deformation or failure under heavy loads, which can lead to structural damage or even collapse.

In addition to structural applications, tensile strength is also important in applications where the sheets are subjected to repeated bending or stretching. For example, in automotive or aerospace components, the sheets may be used to form parts that are subjected to cyclic loading, such as springs or brackets. A high tensile strength helps to prevent fatigue failure, which can occur when the material is subjected to repeated stress over time.

Conclusion

In conclusion, the tensile strength of stainless steel sheets is a crucial property that determines their ability to withstand pulling forces without breaking. The tensile strength can vary depending on several factors, including the grade of stainless steel, the manufacturing process, and the thickness of the sheet. As a supplier of stainless steel sheets, I understand the importance of providing high-quality products that meet the specific requirements of my customers. Whether you're looking for a sheet with a high tensile strength for a structural application or a sheet with excellent formability for a decorative application, I can help you find the right solution.

If you're interested in learning more about the tensile strength of stainless steel sheets or have any other questions about our products, please don't hesitate to contact me. I'm always happy to provide expert advice and assistance to help you make the best decision for your project. Let's start a conversation about your stainless steel sheet needs and explore how we can work together to achieve your goals.

References

- ASM Handbook, Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys

- Stainless Steel: A Practical Guide, Second Edition by George E. Totten and D. Scott MacKenzie

- The Metal Construction Association's Steel Construction Manual